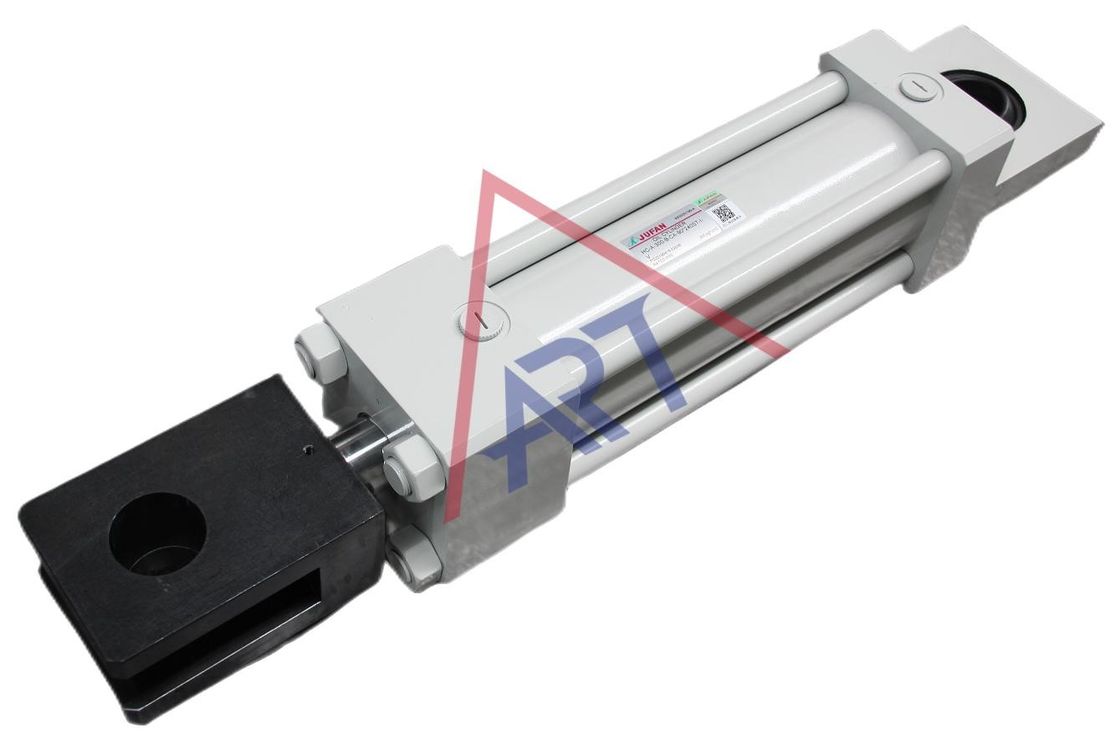

Single-acting and double-acting hydraulic cylinders are types of actuators used in hydraulic systems. The main difference between them lies in how they utilize hydraulic fluid to generate motion.

-

Single-Acting Hydraulic Cylinders:

- These cylinders have one port through which hydraulic fluid enters.

- The hydraulic fluid is used only on one side of the piston to create motion.

- The return of the piston is usually achieved by an external force, such as a spring or an external load.

- Common applications include where the load needs to be moved in one direction only, and there is an external force to retract the piston.

-

Double-Acting Hydraulic Cylinders:

- These cylinders have two ports—one for fluid to enter and another for fluid to exit.

- Hydraulic fluid is used alternately on both sides of the piston to extend and retract it.

- Double-acting cylinders are more versatile as they can perform work in both directions.

- They are commonly used in applications where precise control over the extension and retraction of the piston is required.

In summary, the primary distinction is that single-acting cylinders use hydraulic fluid on one side of the piston, typically relying on an external force for the return stroke. On the other hand, double-acting cylinders use hydraulic fluid on both sides of the piston, allowing for controlled movement in both directions. The choice between them depends on the specific requirements of the hydraulic system and the application at hand.

What is linear guide system?

A linear guide system refers to the overall arrangement or setup that incorporates linear guides to facilitate controlled and precise linear motion. It typically consists of several components:

Linear Guide Rails: These are long, straight rails that provide a smooth and flat surface along which the linear motion will occur. They often have features like grooves or tracks to accommodate the carriage.

Carriage or Slider: The carriage is the component that moves along the linear guide rail. It is mounted on bearings or rollers to ensure smooth and low-friction motion. The carriage is usually attached to the load or machinery that needs to move linearly.

Drive Mechanism: This is the system responsible for driving the linear motion. It could be a motor, screw, belt, or other mechanisms depending on the specific design and requirements of the linear guide system.

Support Structures: These include brackets, supports, or frames that hold the linear guide rails in place and provide stability to the overall system.

Linear guide systems find applications in various industries, including CNC machines, robotics, automated manufacturing, and other precision machinery where controlled and repeatable linear motion is essential. They are crucial for ensuring accuracy, reducing friction, and enhancing the overall performance of machines and equipment.

Installation

| Symbol |

Name |

Drawing |

Symbol |

Name |

Drawing |

| SD |

Basic |

|

TC |

Intermediate trunnion |

|

| FA |

Rod flange |

|

TA |

Head trunnion |

|

| FB |

Head flange |

|

CA |

Clevis |

|

| LA |

Foot |

|

CB |

Dual clevis |

|

| LB |

End angles |

|

|

|

|

Adjustment and Testing of Hydraulic Cylinder

First, reduce the working pressure inside the cylinder to around (0.5-1) MPa. Then, make the piston rod perform reciprocating motion and open the exhaust plug for exhaust.

The method of opening is as follows:

When the piston reaches the end of its stroke, open the exhaust plug at the moment when the pressure rises, and immediately close it before the return begins. During the exhaust process, you can hear a hissing sound, followed by the discharge of white and turbid foamy oil. When the air is completely discharged, the oil sprayed out will be clear. Exhaust completeness can be judged with the naked eye.

If the hydraulic cylinder is equipped with an adjustable buffering device, and the piston is in motion, first set the throttle valve to a position with a lower flow rate, and then gradually adjust the size of the throttle port until the requirements are met.

In addition to performing the above adjustment tasks, it is necessary to check for oil leakage in various sealing components and whether the bolts of the connecting parts are loose, in order to prevent accidents.

Based on the usage of the hydraulic cylinder, schedule regular inspection times and maintain inspection records.

-

Adjustment of Exhaust Device:

-

Adjustment of Buffering Device:

-

Inspection of Various Parts of the Hydraulic Cylinder:

-

Regular Inspection:

Alignment steps:

1.Turn lock nut towards counter clockwise with 1/4circle by wrench.

2.Using hex . wrench to adjust thealignment screw B:

1)clockwise, rod speed will be slow down

2)counter clockwise, rod speed will be up.

3.After alignment ,use hex. wrerch to fix thealignment screwB,and then tighten thecushion nut C to prevent possible

leakage from cushion seal D

4.Tighten the lock nut A

Port and cushion positions

| SD type |

LA type |

|

Standard=A:input port B:Cushion position D:Check valve position

|

|

e.g:order form for position HCA70-LA-C-100X200-B-B-A

Input port=B position

Cushion=A position

Cushion length

|

Bore(mm) |

L |

l |

| 32--63 |

20 |

10 |

| 80--160 |

25 |

15 |

| 180--224 |

30 |

27 |

| 250 |

35 |

32 |

- Should the movement of a cylinder with loading is above 500mm/sec.,

- If the moving speed is higher than 750mm/sec,external reducing speed valves should be used

The application not only for production mechanical machine tools and metal processing equipment, but also can be widely used in actuators of steel, nuclear power plant control, passenger elevators, etc

| Type |

Symbol |

Drawing |

With Bellow |

Heat Proof |

Bore(mm) |

|

|

32,40,50,63,80,100,125,150,180,200,224,250 |

| Double acting |

HCA |

|

HCA-H |

HCA-J |

| Double rod |

HCC |

|

HCC-H |

HCC-J |

| Double rods with alignment |

HCD |

|

HCD-H |

HCD-J |

HC2--A--70-- --SD--C--100--200ST-- -- -- -- -- --

1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13)

| HC2:Tie-Rod Hydraulic Cylinders |

| 1) Type |

A:doubling acting

C:double rods

D:double rods with stroke alignment

|

| 2)Working pressure |

70:70kgf/cm²

140:140kgf/cm²

|

| 3)Performance blank:(standardusage) |

H:with bellow

J:with heat/ erosion proof(the highest temperature is 200℃) |

| 4)Mounting type |

SD/FA/FB/CA/CB/LA/LB/TA/TC |

| 5)Rod size |

C: C class B:B class

note: 1standard:HC-70+C class rod

2.Standard:HC-140+B class rod

3. Please specify when HC-70+B class rod or HC-140+C class rod

|

| 6)Bore(mm) |

32,40,50,63,80,100,125,150,180,200,224,250 |

| 7)Stroke(mm) |

Max.stroke=Max length of stroke-Min. length of stroke |

| 8)Cushion blank: |

no cushion

B:Cushion on bothends

R: Cushion on rod cover

H:Cushion on head cover

|

| 9)Connectors Y |

Y :Yconnector

I:Iconnector

|

| 10)Stroke alignment |

only forward alignment and aligned length < or =stroke length

|

|

11)Port position

|

|

| 12)Cushion position |

|

| 13)Oil seal material blank |

NBR(standard usage),2: PU 3:FPM |

Specifying the needed material while ordering

(1)N:NBR

(2)V:F≤200℃

| Bore |

X |

| 32.40.50 |

1/3.5xstroke+45 |

| 63.80.100 |

1/4xstroke+55 |

| 125.150180.200 |

1/5xstroke+65 |

| 224.250 |

1/6xstroke+80 |

Factory:

Hydraulic cylinder as an actuator:

Absolutely, a hydraulic cylinder is a common type of actuator. An actuator is a device that converts energy into motion, and hydraulic cylinders do this by using the energy of pressurized hydraulic fluid.

Here's how it works:

Input Energy: The input energy is in the form of hydraulic pressure applied to the fluid in the cylinder.

Cylinder Construction: The hydraulic cylinder consists of a cylindrical barrel, a piston, and hydraulic fluid. The piston divides the cylinder into two chambers.

Force Generation: When hydraulic fluid is pressurized, it exerts force on the piston. The force is directly proportional to the pressure and the piston area.

Motion: As the piston moves, it generates linear motion. This motion can be used for various purposes, such as lifting, pushing, pulling, or bending, depending on the design and application.

Hydraulic cylinders are widely used in various industries for heavy-duty applications where high force is required. They're efficient, reliable, and can be precisely controlled, making them excellent choices for actuation in construction equipment, manufacturing machinery, and other mechanical systems.

FAQ

Q1: Are you a manufacturer or a trading company?

We have our own factory, so we can provide the best price as well the first service.

Q2: Do you accept customization or Non-standard products?

Yes, we can customize products as the customers required.

Q3: What is your MOQ?

MOQ depends on our clients needs. Besides, we welcome trial order before mass production.

Q4: How long is your delivery time?

Normally, the delivery time is 7 days if we have stock. If we don't have stock, it needs 15-30 working days. And it also depends on the quantity and requirements of products.

Q5: What are your payment terms?

T/T. If you have any questions, please feel free to contact us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!